Exceptional support from concept to commercialization, so your pharmaceutical devices administer the exact dose when triggered throughout the life of the program.

Drug delivery device and system manufacturing

Simplify your supply chain with a partner that can support you from concept to commercialization and packaging. Paragon Medical will help you with medical device design and development, then produce complete drug delivery products, including providing engineering expertise and testing.

Our facilities offer project management; concept brainstorming, prototyping and testing; product development including specification generation and design iteration testing; plus design verification and validation. Once we scale up for commercialization, we offer production manufacturing including mechanical and electro-mechanical assembly, packaging and external sterilization to accelerate your time to market. With a drug license at our Mansfield location, we can load your device, add drugs to your kit, creating a “combination” production, and provide packaging for your final, sterilized pharmaceutical delivery system.

Whether you need a complete product of a highly engineered component, the Paragon Medical team has the technology, expertise, and quality standards to help move your project forward.

Precision components for drug delivery systems and respiratory devices

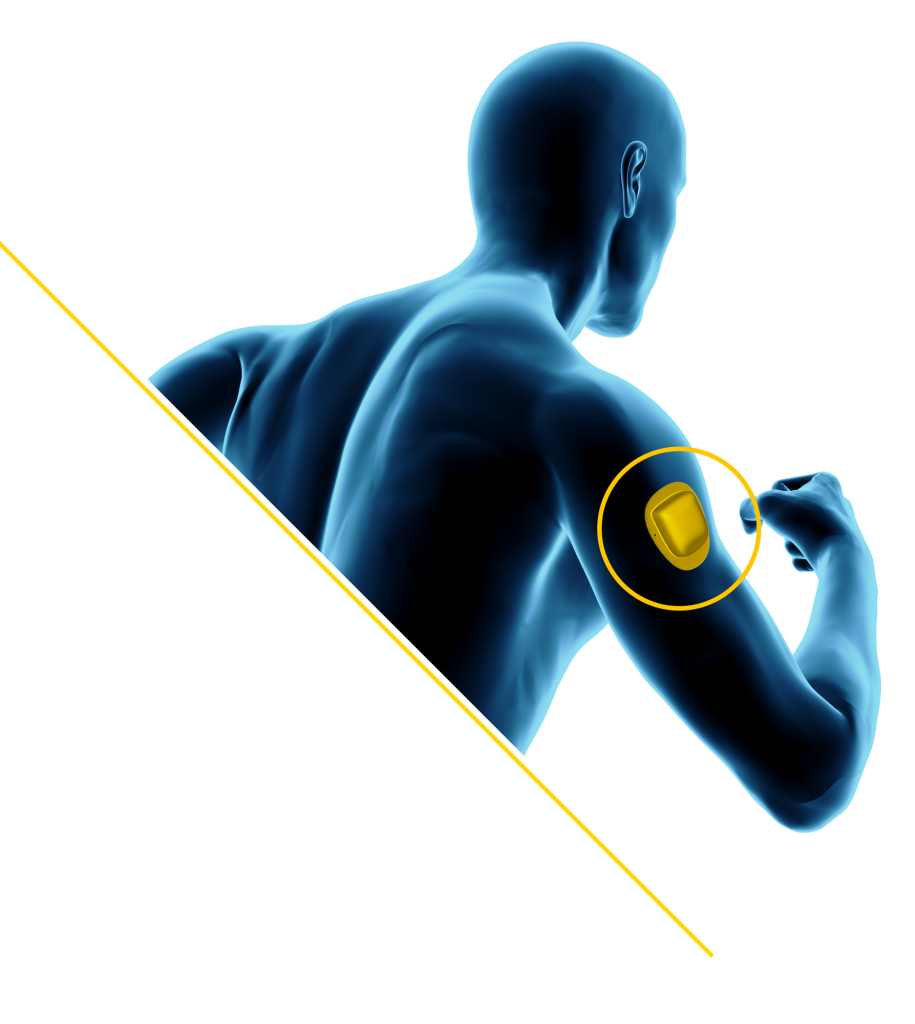

Self-administered drug delivery is one of the fastest growing medical/pharmaceutical segments on a global scale. Increasingly, patient care incorporates pen-like devices to safely inject medicines at home without worrying about of improper dose administration.

Connected devices, also known as IoMT devices, using smart applications to monitor use and collect data are key to successful drug delivery platforms and effective patient care. Paragon Medical’s years of product development support, while optimizing the integration of precision metal components in your device, make us the ideal partner for your project. We’ve manufactured IoMT device and pharmaceutical delivery system components that help control the safety and delivery timing for auto-injectors or respiratory inhalers that disperse drugs including:

- Micro-sized drug delivery springs in wearable delivery systems

- Power springs in a pen device that deliver the drug or needle retraction springs for patient comfort

- Pharmaceutical wire forms / stampings that help optimize circuit and battery connectivity

- Custom-tipped sharps or needles

- RNS removal components

- Anti-fire hardware that prevents accidental triggering of the device

Reliability is not an option when it comes to delivering the precise dose every time. Although self-administered drug therapies are expanding rapidly in the global market, many of today’s drug delivery systems are monitored by a medical professional via wireless communication. From the drug delivery springs, pharmaceutical stampings and wire forms, bellows, custom battery contacts, and timing contacts that ensure critical network communication circuits perform reliably, Paragon Medical can help you meet your objectives for new drug delivery system components and products.

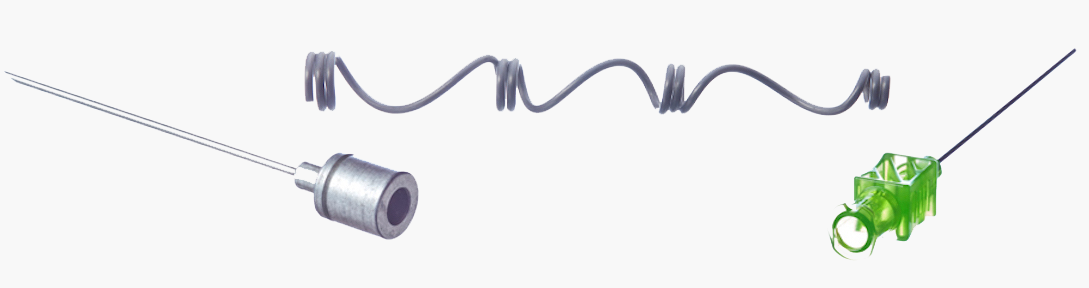

Auto-Injectors and Drug Delivery Springs

Paragon Medical specializes in drug delivery system components, including drug delivery springs. Many of the auto-injectors on the market use metal drug delivery springs to control the device’s needle and achieve precise delivery of the drug. The drug delivery springs in each device often include a main spring and return spring that must be designed so they don’t damage plastic parts and compromise the integrity of the device.

Our expertise extends to micro-components that can help decrease the size of the devices and support connectivity for smart devices and smart drug delivery devices. Major applications include diabetes devices and wearable medical devices. Paragon Medical’s engineers can provide the design expertise to support device and component development for these and other demanding applications. We support pharmaceutical and medical OEMs from design and prototyping to full production.

Ideal Applications

Paragon Medical provides wire forming, tube cutting, and grinding of micro-sized metal parts to precise tolerances along with custom-tipped sharps with complex geometries. Our medical manufacturing capabilities are ideal for components including:

- Retractable needles for pen-like delivery devices

- Pharmaceutical springs for nebulizers and inhalers for precise dosage controls

- Battery and timing contacts for IoMT devices

Product and component types

Paragon Medical is an end-to-end solution provider for drug delivery system manufacturing. We support complete product design and development from concept to production manufacturing, assembling, and packaging. We also provide metal and plastic components for drug delivery devices.

- Actuation Components

- Anti-Fire Hardware

- Battery Contacts

- Biologic Devices

- Custom-Tipped Needles

- Custom-Tipped Sharps

- Dialysis Devices & Kits

- Drug Delivery Devices

- Drug Delivery Systems including auto-injectors, neurological infusion products, and peripheral infusion products

- Drive Springs

- Electrical Contacts

- Fluid Management Sets

- Pharmaceutical Delivery Systems

- Pins

- Retraction Springs

- Rigid Needle Shield Components

- Safety Components

- Shielding Components

- Wearable Device Components

Processes

Across our facilities, we use specialized manufacturing technologies to ensure our customers receive only the highest quality products and services. Our current processes include:

- Coiling and wire forming

- Laser cutting, ablation, and welding

- Tubing and needle fabrication

- Precision machining

See more of our processes and technologies.

Materials

Our highly skilled teams work with medical-grade materials proven to provide the best solutions and can assist in the recommendation and selection of materials for specific applications.

CONTACT